6000+

Glass services

delivered in the last 5 years

£10m+

Funding

secured for project work

1000+

Clients

we've worked with in the last 5 years

68

Countries

we have worked in

Expertise & Leadership

Services

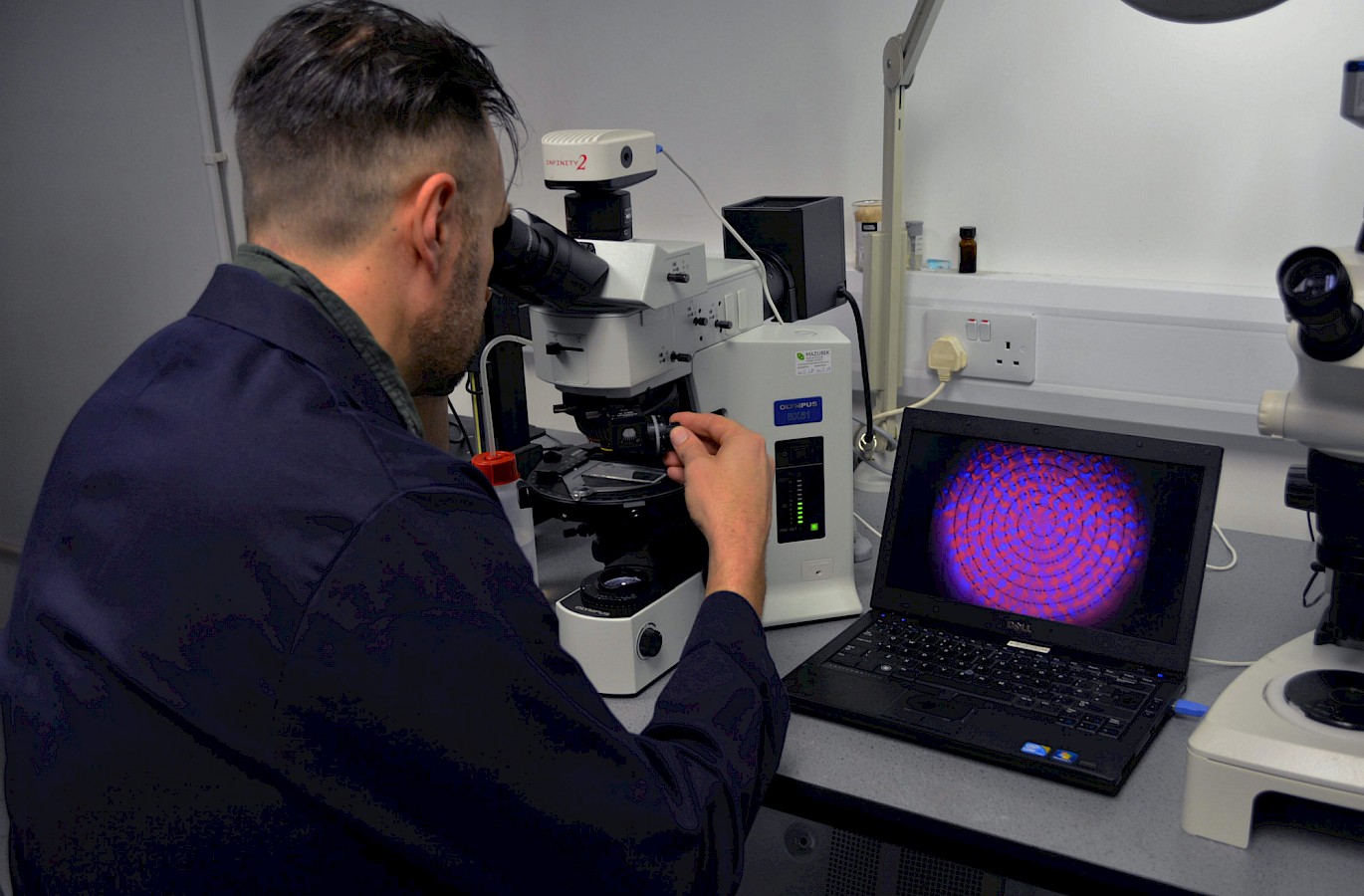

Glass failure analysis

Glass failure (or fracture) analysis is a powerful tool combining glass fractography and microscopy to diagnose and determine the root cause of a breakage or product failure. We also complete preventative quality assessments to potentially stop issues occurring in the future. We provide analysis for products spanning all sectors, including food and drink packaging, domestic glass, furniture, scientific glassware and pharmaceutical packaging.

Products this service is relevant to:

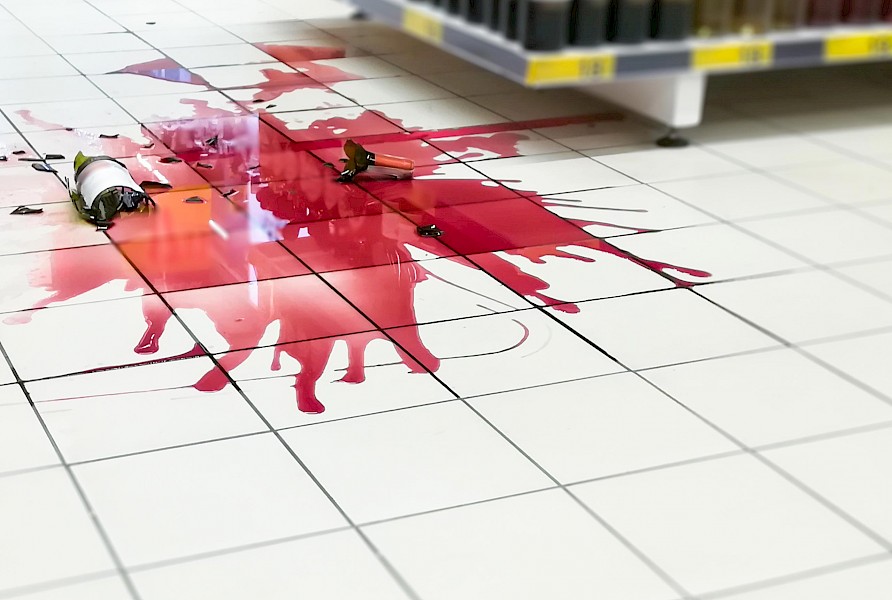

Glass production, processing, and packing line audits

Our glass production and processing experts provide manufacturers, suppliers, brand owners and customers with line and process audits to optimise glass production, processing, and food and drink operations. We work with companies involved in all stages of glass supply, from raw materials through to the end product. In emergencies, we can undertake site visits at short notice to identify issues quickly, allowing production to resume and minimising financial losses.

Products this service is relevant to:

Glass defects and contamination analysis

Our technical experts analyse glass composition and causes of defective glass to quickly resolve your production issues. We undertake composition analysis of glass inclusion defects, stone, cord, knot, bubbles and blisters, and we examine surface contamination, delamination, misting and blooms. We also assess forming defects in glass manufacturing and quality concerns in finished products.

Areas we work in:

Glass composition analysis

We provide ISO/IEC 17025-accredited composition analysis, enabling glass manufacturers to confirm that glass has been made as intended, and potentially determine the cause of a problem. Our methods are created specifically for glass, so they’re accurate and reproducible.

Areas we work in:

Bespoke glass design, development and manufacture

Our experts provide a series of small-scale melting trials to confirm the suitability of new raw materials in glass production. We use comparative melting trials to establish differences between compositions or refining systems. The normal trial we offer is based on melting four glasses. The melts are all made to produce 250g of glass. We study the melting and refining of each formulation for 30, 60, 90 and 120 minutes, at a temperature comparable with the customer’s melting temperature.

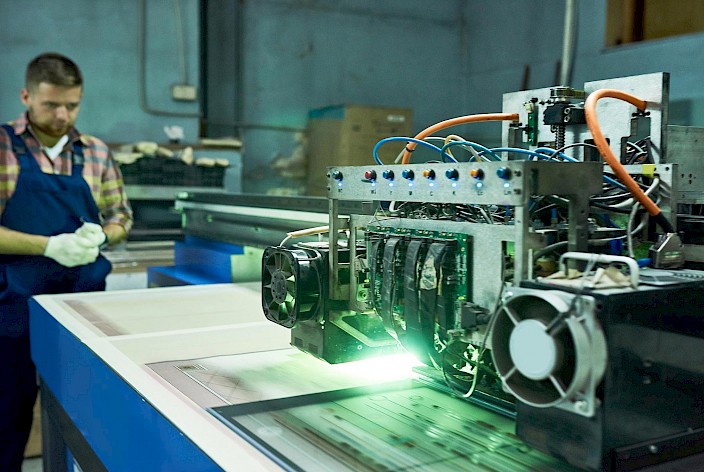

Laser process development

We can help you develop laser processing techniques tailored specifically to glass materials. We have specialist expertise in areas including laser welding technologies, glass laser processing and cutting, additive manufacture (3D printing) and targeted property modification. Working together, we can develop new products for sectors such as micro-machining, biomedical technologies and advanced optics. We support and collaborate with partners and customers spanning academia and industry.

Areas we work in:

Glass durability and elemental migration analysis

Our experts can verify that your glass complies with international and industry standards. Our durability analysis and testing ensures it’s fit for purpose, it provides the appropriate level of chemical resistance, and it meets all required standards. This is vital for chemically sensitive products such as parenteral pharmaceuticals. However, it is also important to ensure the safety of packaging, preparatory surfaces and vessels for foods and drinks.

Areas we work in:

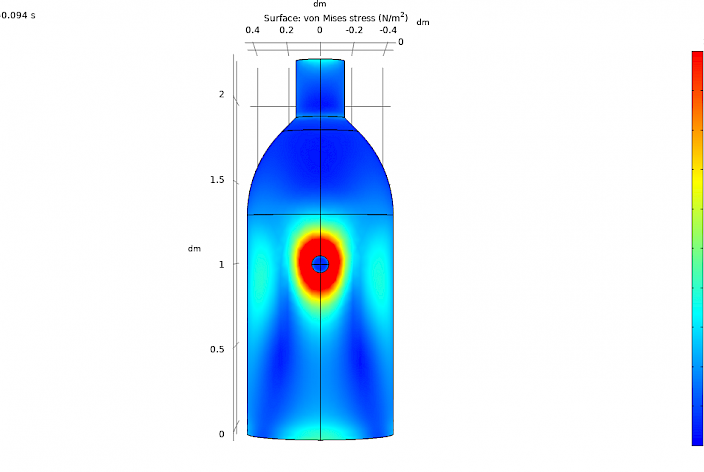

Finite element analysis (FEA) modelling

We use finite element analysis (FEA) modelling to provide insights into a vast range of processes and scenarios. We combine our FEA software capability with expertise in glass materials and glass manufacture to model heat transfer and stress generating processes, ranging from furnaces to laser processing. Our finite element analysis modelling provides vital information that allows you to minimise costs and reduce the probability of failures.

Areas we work in:

Recent projects

Project

EnviroAsh investigates the potential for using biomass and other wastes as raw materials across the foundation industries

This project has identified opportunities to convert waste materials and other by-products from across the foundation industries into new raw materials for glass, ceramic and cement products.

Project

AI6S project examines energy and waste reduction in the foundation industries

We will be taking part in the AI6S project which will develop a novel toolkit for process optimisation across the glass, cement, paper, ceramics, metals and bulk chemicals industries.

Project

A market survey of applications and manufacturing processes of foam glass

BRE and Glass Technology Services investigated the use of waste material to generate a building product or high value lightweight aggregate for insulation purposes.

Project

Bottle rightweighting - beer, cider and spirits

Bottle rightweighting - a process of packaging design and production to optimise packaging weight, whilst taking into account the requirements of all stakeholders in the supply chain, including manufacturers, brand owners, fillers, retailers, consumers and the environment.