Free resources

Written guide — How to switch packaging suppliers successfully

The increase in vaccine production due to the COVID-19 pandemic has seen an increased demand for pharmaceutical glass packaging. This has impacted the supply chain, leaving some companies with no choice but to look for new glass suppliers.

This guide explains how smaller and mid-size companies who deal with glass manufacturers directly can successfully change suppliers whilst meeting packaging requirements.

Poster — Vial anatomy and classification

This poster provides guidance on the anatomy and classification of pharmaceutical vials.

The resource clearly defines anatomical terminology for tubular and moulded glass vials together with a table that summarises the suitability of glass container types based upon the general recommendations of the European (Ph. Eur) and United States Pharmacopoeia (USP).

Webinar replay — Pharma glass recalls: Causes and preventative measures

The consequences of pharmaceutical product recalls can be huge. Not only is company reputation and profits at stake, but most importantly, deviating pharmaceuticals can cause patient harm and even death.

This video replay is a combination of three webinars and each session is focused on a specific cause of product recalls.

Written guide — Pharma glass recalls: Causes and preventative measures

This document summarises the key takeaways from our three-part webinar series – Pharma glass recalls: Causes and preventative measures.

Each webinar focused on different causes of pharmaceutical glass packaging recalls including drug product and glass interaction, cracking and breakages, and dimensional non-conformance.

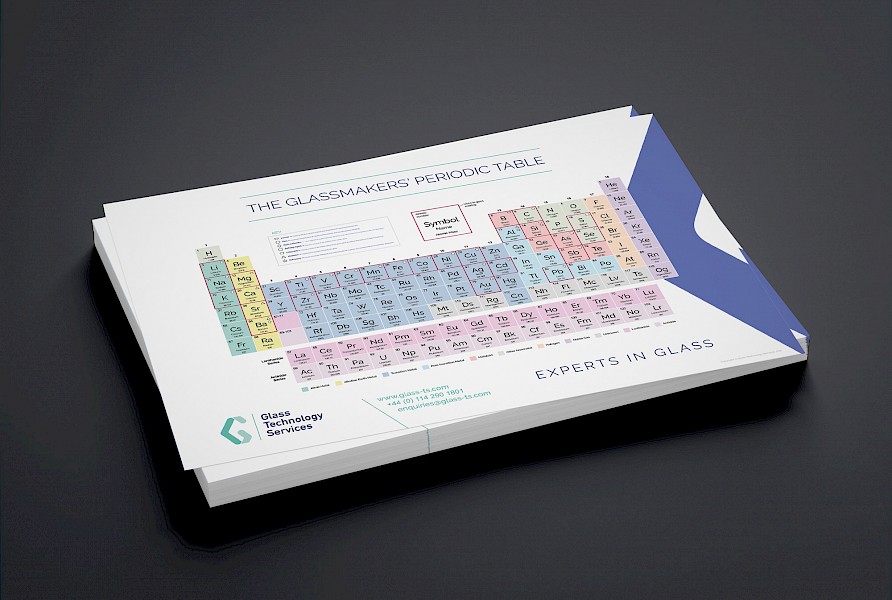

Poster — Glassmakers' periodic table of elements

To celebrate the 150th anniversary of the periodic table of elements we released a glass-specific periodic table.

This unique poster highlights the elements commonly used by glass technologists and a graphical legend indicates the role that these elements take in the glass manufacturing process. These include network formers, flux agents, optical modifiers, refining agents, stabilisers, colourants and those found within refractory materials commonly used in glass making.

Client testimonials

Our glass experts

We have over 40 years’ combined experience in performing chemical and pharmaceutical testing for world-leading brands in the glass and pharmaceutical industries. Our experts have published scientific papers in this area and are members of the TC2 and TC12 technical committees.