Food & drink leadership and expertise

Our experts work with global brands across the food and drink supply chain to resolve issues associated with glass production. We have the specialist knowledge to investigate the root cause of problems and identify ways to prevent issues from occurring in the future.

Food & drink services

Glass failure analysis

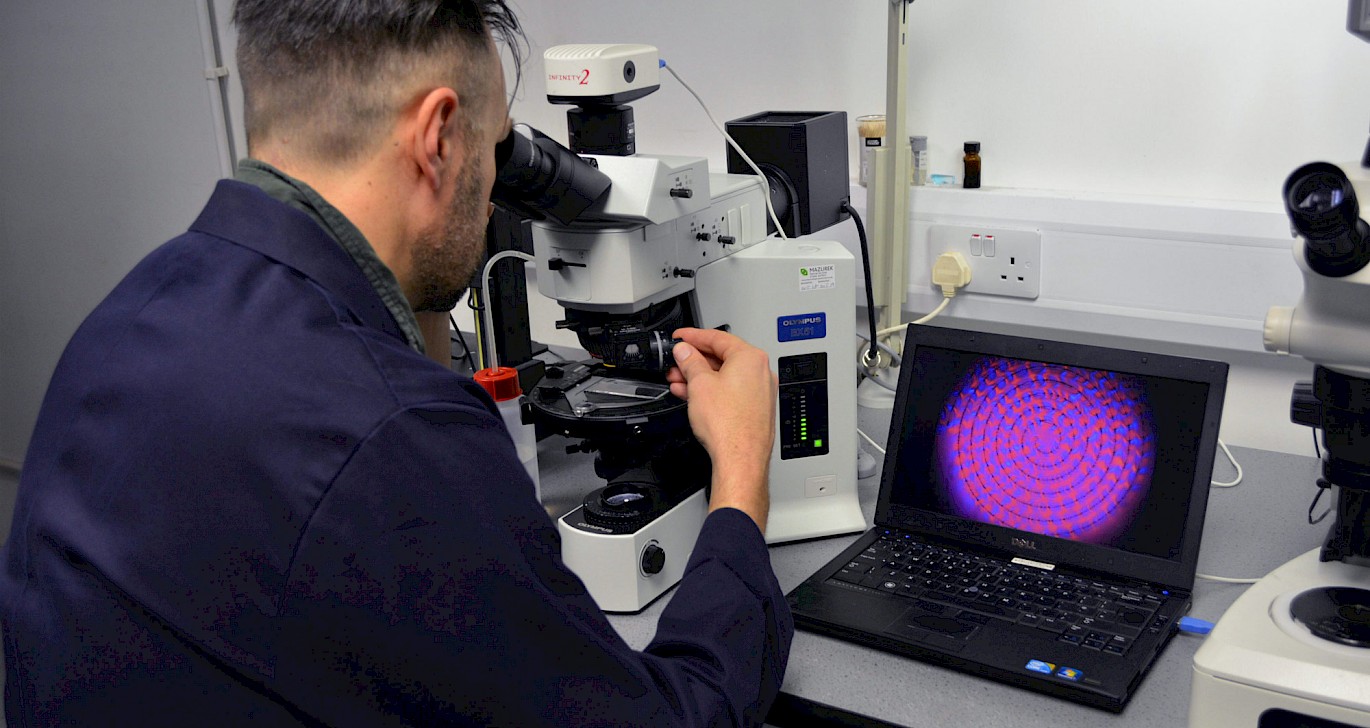

Food and drink manufacturers are ultimately responsible for ensuring the stability of the containers their products are supplied in. Using glass failure (or fracture) analysis, we can offer assurances by completing preventative quality assessments and performance testing to ensure due diligence.

Our glass failure analysis also enables us to determine the root cause of a glass breakage in the event of product failure. This comprehensive service combines glass fractography, laboratory analysis and microscopy, on-site investigation, auditing, inspection and expert witness support (if required by a failure scenario).

As well as specialist expertise, we can guarantee independence, confidentiality, speed and flexibility.

Products this service is relevant to:

Glass container design

We have partnered with Rockfield to develop glass container design packages that help brand owners reduce risk in the container design process.

Our fully packaged service takes you from initial concept through to a product ready for market. Rockfield’s software Elfen aids in the design, production and quality control of glass containers. We combine this latest technology with years of glassmaking experience to provide practical, representative simulation tools that you can benefit from.

Our experts also assess and critique glass designs at early stages in the production process, and we advise on design features that will influence the mechanical strength of the finished product.

Products this service is relevant to:

Fitness for purpose testing

Our extensive and advanced tests determine whether your glass container is suitable against relevant international, national, industry or in-house standards and specifications.

We provide a comprehensive range of mechanical and physical product performance testing and analysis for a range of glass products. They include domestic and trade drinking glasses, bottles and jars, and specialist glassware.

Our experts can assess the capacity and headspace, coatings performance, impact resistance, internal pressure resistance, thermal shock resistance and vertical load resistance. The rigorous tests will determine whether the products are fit for purpose and can perform under the strains they are expected to withstand.

Products this service is relevant to:

Glass foreign body and fragment analysis

Foreign bodies, objects, glass fragments, glass particles and other contaminants found in products are a serious issue at any point in the supply chain – especially in food and drink containers.

Through analysis, we can identify whether the foreign object was introduced during the manufacturing, processing or filling stage, or potentially by the customer after purchase. And we can work with you to resolve the issue to potentially prevent it from happening again.

Where an injury or complaint is involved, our expert witness service can provide a specialist report and testimony. Our standard service is UKAS accredited. We also offer a rapid response service, with results issued within 24 hours of receiving the sample.

Glass composition analysis

We can verify and benchmark compositional variations in your food and drink containers. Our experts can analyse standard and exotic glass compositions, including commercial (soda-lime-silicate) and borosilicate glass. And they can diagnose production, batch and contamination issues.

We use ISO/IEC 17025 accredited composition analysis to identify glass, raw materials, refractories, dusts and other inorganic materials. The analysis is typically carried out by x-ray fluorescent spectrometry (XRF). But for exotic/specialist glasses, specific requirements or trace element analyses, additional methods can be used. They include wet chemistry, atomic absorption spectroscopy (AA) and inductively coupled plasma optical emission spectrometry (ICP-OES).

Colour analysis

Our experts can verify, match, develop and benchmark batch variations in your glass containers using UV visible spectrophotometry. We use coordinates that set out limits and tolerances for product colour to ensure your specific branding or performance requirements are met.

These services include colour analysis, comparison and deviation, verification against client specifications, and verification of ‘premium’ flint, or ‘extra white’ quality. The analysis provides colour coordinates under the CIELAB colour space, which includes all perceivable colours, exceeding that of the common RGB or CMYK spaces. The colour coordinates are also device independent.

Environmental services

We work with companies throughout the glass supply chain on environmental projects such as recycling schemes, glass re-use and specialist raw material recovery, lightweighting of glass products, emissions control and environmental impacts.

Our stack emissions team is accredited by the Environment Agency's Monitoring Certification Scheme, and can analyse various process emissions. We then interpret the results and advise on abatement strategies.

We can also ensure you fulfil statutory obligations by completing workplace monitoring, tailored to your individual factory situation and the latest legislation.

Food contact elemental migration

We analyse food and drink containers to verify that they meet the appropriate level of chemical resistance and comply with international and industry standards. This is important to ensure the safety of packaging, preparatory surfaces and vessels for food and drink.

Durability analysis involves determining the environmental and chemical resistance of the product through exposure to a range of acids, bases, water, or other simulants. The analysis determines and quantifies whether any heavy metal leaching from the glass occurs.

Analysis is typically provided for lead and cadmium. However, a wide range of trace elements and custom matrices can be provided to meet your requirements.

Client testimonials

Additional services

R&D and innovation

We have unrivalled glass expertise across a broad range of sectors and can help you develop and optimise your scientific glass applications.

Training and webinars

Our in-house and external training courses teach organisations about various areas of glass production, such as packaging, analysis, and performance.

Consultancy

Our technical experts can provide you with market advantage, knowledge and technical input to processes or products, or develop entirely new and innovative glass formulations, uses or treatments.